Commercial roofing managers and owners in the Cincinnati to Dayton region that Roofing Annex serves are typically by the many options available for low slope roofs. Before we compare single ply roofing membranes we outline what the three group types are. All of them are fairly complex systems and some have strange names or abbreviations to cause more confusion.

Group #1 – Thermoset Membranes

The polymer materials in these single ply roofing membranes chemically crosslink. This means chemical adhesives applied at the seams cures or vulcanizes the membrane strips into one giant membrane. There are several players in this category which is also defined as the synthetic rubber membrane group.

There are five common subcategories of thermoset roof membranes:

- Ethylene propylene diene terpolymer (EPDM)

- Chlorosulfonated polyethylene (CSPE)

- Epichlorohydrin (ECH)

- Neoprene (CR)

- Polyisobutylene (PIB)

The most common thermoset roof membrane is EPDM. This frontrunner of the pack will be our comparison product. Note EPDMs main characteristics:

- Sheet widths range from 7.5 feet to 50 feet wide.

- Sheets are typically 45 mils and 60 mils thick.

- Seams are sealed using liquid adhesives or special formulated tape.

- The membranes commonly are black, but white is available.

Group # 2 – Thermoplastic Membranes

This family of single ply roofing membranes are very like the thermosets, but there’s no chemical cross-linking or vulcanization. The membrane strips are heat or chemical welded to create a single ply. Proper welds are as strong as the material. There are four common subcategories of thermoplastic roof membranes.

- Thermoplastic Olefin (TPO)

- Chlorinated Polyethylene (CPE)

- Polyvinyl Chloride (PVC)

- PVC Alloys or Compounded Thermoplastics

- Copolymer Alloy (CPA)

- Ethylene Interpolymer (EIP)

- Nitrile Alloys (NBP)

- Tripolymer Alloy (TPA)

The most common thermoplastic roof membranes are PVC (chemical weld) and TPO (heat weld). PVC is common simply because it was the frontrunner until TPO came into its own with more adopters. Thus, for this group we will look at TPO when comparing single ply roofing membranes.

TPO membranes are produced by calendering with lamination, extrusion with lamination, or extrusion-coating techniques. TPO sheets are a blend of polypropylene and ethylene propylene polymers and usually are reinforced with polyester. Note EPDMs main characteristics:

- Sheet widths range from 6 feet to 12 feet wide

- Sheets are typically 40 mils to 100 mils thick

- Seams are sealed by heat welded with hot air

- TPO membranes commonly are white but can allow for a colorant

- Flame retardants are added

- UV absorbers and other proprietary substances are added as needed

Group #3 – Modified Bitumen Membranes

These membranes combine asphalt with modifiers and reinforcement materials. They are often a “sandwiched” roofing material. These materials can perform well but they are not as advanced as the other two groups. Many roofers refer to modified bitumens as “torch-down” roofs because a large flame throwing torch melts the asphalt so that seams can be joined together.

There are two types of modified bitumen (MB) roofing membranes:

- SBS polymer-modified bitumen membranes commonly are installed via hot mopping asphalt (similar to BUR systems) or cold adhesive. Some SBS modified membranes are self-adhering; that is, they contain an adhesive backing.

- APP polymer-modified bitumen membranes typically are heat-welded or torch-applied. Consumers should be cautioned that NRCA does not recommend torch-applying a modified bitumen membrane sheet directly to a wood deck.

Generally, APP modifiers impart a “plasticized” quality to asphalt, and SBS modifiers impart a “rubberized” quality to asphalt. MB membranes and EPDM, a thermoset membrane, often are confused by consumers because of colloquialisms used by roofing contractors. MB and EPDM membranes are sometimes called “rubber roofs.”.

Modified bitumen is inexpensive, easy to apply in the case of SBS, and great for DIY types. This combines with its short lifespan make it a non-competitor for larger commercial roofing spaces.

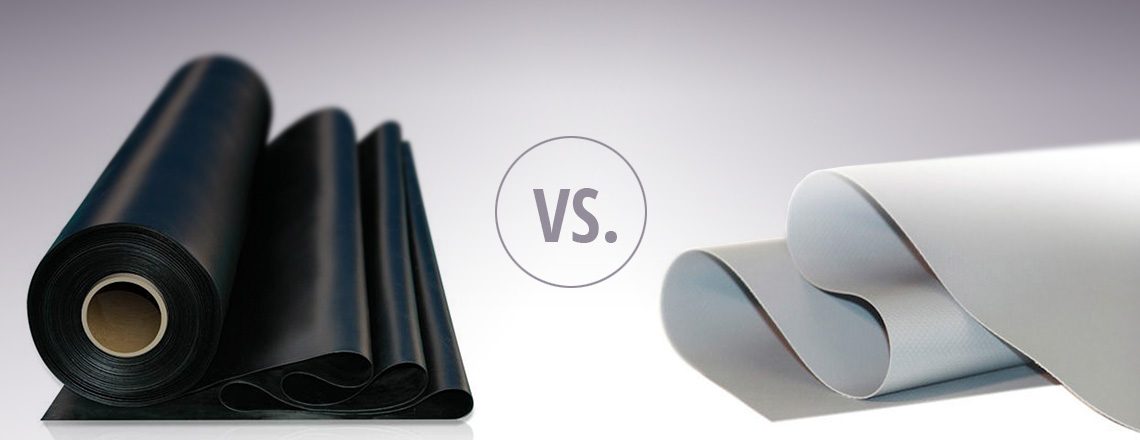

When Comparing Single Ply Roofing Membranes its Really TPO vs EPDM

We think you’ll agree that these two membrane types are already the one you’ve heard the most about prior to this article. If you have a low slop (flat) commercial roof it most likely has a leading thermoset or thermoplastic membrane on it. Now we can get to the simple comparison. Our head-to-head comparison takes into account a range of good to top tier products per each single ply membrane type. We awarded each a plus one or minus one to give a final tally of overall prowess of each membrane type if it gave more options or value – or – had a deficit or negative/detractor.

| EPDM | TPO | |

| Warranty Timespans | 10-35 | 10-35 |

| Warranty strength value | Average | Wide (poor to outstanding) |

| Cost effective | Yes | Yes |

| Lifespan | 20-50 years | 15-50 years (potentially) |

| Thickness range | 45-60 mils | 40-100 mils +1 |

| Maintenance costs (low to high) | Medium -1 | Low |

| Energy savings | Little to none | Light to significant +1 |

| Roof heat buildup in summer | Yes -1 | Little |

| Suitable climate | Colder -1 | Most (cold to hot) |

| Environmentally friendly material | Yes – made of recycled materials | Yes – 100% recyclable |

| Color options | Barely – Black and white | Yes – Many +1 |

| Inexpensive repairs | Typically | Yes +1 |

| Track record (time in use) | Solid +1 | Short track record -1 |

| Sheet size | Medium to huge +1 | Small to medium |

| Chemical resistance | Very poor -1 | Excellent +1 |

| Requires specific skills to install | Yes | Yes |

| Pollution from water runoff | None | None |

| Shrinkage with extreme heat | Some | Some with extreme heat |

| Seam failure level after 10 years | Moderate to low -1 | Very low to none |

| Installation speed | Average | Below to above average -1 |

| Weather rating | Average | Average to very good |

| Tally | -3 | +3 |

When we’re comparing EPDM and TPO products looking at a spread and mean we get a 6-point spread in favor of TPO. As a GAF® Master Select™ roofing contractor, Roofing Annex uses the top rated TPO lines made by GAF, EverGuard™ and EverGuard Extreme™. Combine the best products with top notch installations, and the best warranty, and TPO picks up 2 or 3 more points over the best EPDM.

Not all roofers will agree with this. Some make their money off an expertise with EPDM that goes back decades. Other simply bash TPO to discredit it because of the money to be made on EPDM maintenance and repairs. Some just don’t trust the manufacturers’ claims of longevity since it’s untested out of the lab to last a lifetime. We agree that real world scenarios and time are a risk factor but GAF and independent labs agree that 60 mil EverGuard and EverGuard Extreme, as well as Firestone® TPO products, have no problem handling 37 years of extreme abuse.

A lot of the anti-TPO rhetoric you’ll hear is also based on confusion with thermosets like PVC and the various PVC alloys which have chemically bonded seams. In the past, these seams have had a negative track record. PVC had other pitfalls that would have sunk it below EPDM by a few points in a similar tally. The thermoset family legacy haunts TPO but it is slowly making a significant impact.

Call the commercial roofing pros at Roofing Annex to learn more about upgrading your flat roofing to a TPO membrane from GAF. We can perform an in-depth evaluation of your roof and let you know it’s condition and provide a free estimate for its replacement.

513.685.9092